In the realm of materials engineering and manufacturing, Cast Aluminum stands out as a remarkable material offering both strength and versatility. This lightweight yet durable metal has become a staple in various industries, from automotive to cookware, due to its unique properties and adaptability.

The Strength of Cast Aluminum

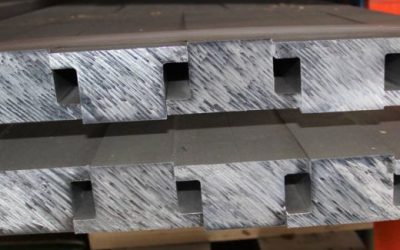

Cast aluminum refers to aluminum that has been melted and poured into a mold to achieve a desired shape. This process allows for the creation of complex and intricate designs that are both strong and lightweight. The strength of cast aluminum is attributed to its composition and the casting process itself, which can involve several techniques such as sand casting, die casting, and permanent mold casting.

Key Attributes of Cast Aluminum:

- Lightweight: One of the most significant advantages of cast aluminum is its low density, making it ideal for applications where weight reduction is crucial.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, enhancing its resistance to corrosion and making it suitable for outdoor and marine environments.

- Thermal Conductivity: Cast aluminum is an excellent conductor of heat, which is why it is commonly used in cookware and heat exchangers.

- Recyclability: Aluminum is fully recyclable, which contributes to its sustainability and appeal in eco-conscious markets.

Versatility in Applications

The versatility of cast aluminum is evident in its widespread use across different sectors. Its ability to be molded into various shapes and sizes makes it an attractive option for manufacturers seeking to innovate and optimize their products.

Common Applications:

- Automotive Industry: Cast aluminum components are prevalent in vehicles, used in engine blocks, wheels, and frames to reduce weight and improve fuel efficiency.

- Cookware: Due to its excellent heat distribution properties, cast aluminum is a popular choice for pots, pans, and baking sheets.

- Aerospace: In the aerospace industry, the need for lightweight yet durable materials makes cast aluminum an ideal candidate for aircraft parts.

- Electronics: The metal’s thermal conductivity and ability to dissipate heat make it suitable for electronic housings and heat sinks.

These applications demonstrate the material’s adaptability and the broad range of benefits it offers to different industries. For more detailed insights into the differences between cast and wrought aluminum alloys, you can explore this comprehensive guide on cast aluminum .

In conclusion, cast aluminum is a material that exemplifies strength and versatility, making it invaluable in various applications. Its lightweight nature, corrosion resistance, and excellent thermal conductivity contribute to its widespread use, from automobiles to household cookware. As industries continue to seek materials that offer both performance and sustainability, cast aluminum remains a top choice, unlocking new possibilities for innovation and efficiency. Whether you’re designing a new product or seeking to improve an existing one, the benefits of cast aluminum are difficult to overlook, making it a cornerstone in modern manufacturing and engineering.