When it comes to hauling trailers, boats, or recreational vehicles, ensuring the safety and reliability of your towing setup is paramount. One crucial component that often determines the success of a towing operation is the coupling device that connects your trailer to your tow vehicle. For those searching for secure and compliant solutions, Hitch Couplers that meet American road standards are essential for peace of mind and legal compliance.

The Importance of Road-Compliant Hitch Couplers

Safety on the road begins with proper equipment. American road standards are set to ensure that towing components, including couplers, can withstand the stresses and loads encountered during travel. Using hitch couplers that adhere to these standards is not only a matter of legal compliance but also a fundamental aspect of road safety for you and others.

Hitch couplers that meet these regulations are designed and tested to handle specific weight capacities, resist corrosion, and maintain a secure connection throughout your journey. This means you can confidently tow knowing your equipment is up to the task, whether you’re traversing highways or navigating rough terrain.

Key Features to Look for in Quality Hitch Couplers

Choosing the right coupler involves more than just matching the size. Here are some essential factors to consider:

- Certification: Look for products that clearly state compliance with American road standards, such as SAE or DOT certifications.

- Material Strength: Durable steel construction, often with corrosion-resistant coatings, ensures longevity and reliability.

- Weight Rating: Always verify that the coupler’s Gross Trailer Weight (GTW) and tongue weight ratings match or exceed your trailer’s requirements.

- Secure Latching Mechanism: A robust and easy-to-use latch prevents accidental uncoupling and provides peace of mind.

- Ease of Maintenance: Consider couplers with accessible grease fittings or simple mechanisms for easy upkeep.

By focusing on these features, you minimize the risk of equipment failure and maximize towing safety.

Installation and Maintenance: Best Practices

Proper installation and regular maintenance are key to ensuring your coupler performs as intended. Follow these best practices:

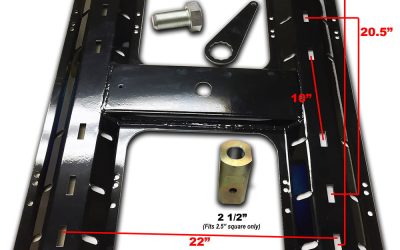

1. Accurate Fit: Ensure the coupler size matches your trailer tongue and hitch ball exactly. An improper fit can lead to dangerous disconnects.

2. Torque Specifications: Tighten all bolts and fasteners to the manufacturer’s recommended torque settings to prevent loosening during transit.

3. Routine Inspection: Before each trip, inspect the coupler for signs of wear, rust, or damage. Replace any worn components immediately.

4. Lubrication: Apply grease to the moving parts as specified in the product manual to reduce friction and prevent corrosion.

Taking these steps helps maintain the integrity of your towing setup and extends the lifespan of your equipment.

Staying Compliant with American Road Regulations

American road standards exist to protect drivers and ensure uniformity in towing practices. Non-compliance can lead to fines, liability issues, or even accidents. Always keep documentation for your coupler’s certification and review state-specific requirements for towing, as regulations can vary.

In summary, choosing hitch couplers that meet American road standards is a critical step in ensuring safe, legal, and reliable towing. Focus on certified, high-quality products, and commit to proper installation and maintenance. By doing so, you not only protect your investment but also contribute to safer roads for everyone. Whether you’re a seasoned hauler or gearing up for your first big trip, the right coupler makes all the difference in towing confidence and security.