In today’s rapidly evolving industrial landscape, the role of an Industrial Control Panel Manufacturer is pivotal in enhancing the efficiency of manufacturing processes across the United States. These manufacturers design and produce control panels that serve as the nerve center for machinery and systems, ensuring seamless operations and optimizing productivity.

The Role of Industrial Control Panels

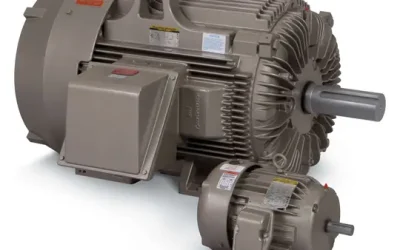

Industrial control panels are essential components in various sectors, including automotive, aerospace, food processing, and more. These panels house the electrical components and controls necessary to manage the machinery and processes within a facility. By consolidating control mechanisms, they simplify operations, reduce downtime, and enhance safety.

Key Benefits of Industrial Control Panels

- Increased Efficiency: Control panels streamline operations by centralizing control functions, allowing for quicker adjustments and real-time monitoring of system performance.

- Enhanced Safety: By integrating safety features such as emergency stop buttons and alarms, these panels help prevent accidents and ensure compliance with safety standards.

- Cost Reduction: Efficient control panels reduce energy consumption and maintenance costs by optimizing machine performance and identifying potential issues before they escalate.

- Customisation: Manufacturers can tailor control panels to meet specific industry needs, ensuring compatibility with existing systems and processes.

How Manufacturers Enhance Efficiency

An Industrial Control Panel Manufacturer plays a crucial role in boosting manufacturing efficiency by employing advanced technologies and innovative design principles. Here’s how they do it:

- Integration of Advanced Technologies: By incorporating state-of-the-art technologies like programmable logic controllers (PLCS) and human-machine interfaces (HMIS), manufacturers ensure that control panels are capable of handling complex operations with precision.

- Focus on Quality and Reliability: High-quality materials and rigorous testing procedures ensure that control panels can withstand harsh industrial environments and perform reliably over time.

- Emphasis on Energy Efficiency: Manufacturers design panels that optimize energy use, contributing to sustainable practices and reducing operational costs for businesses.

- Comprehensive Support and Maintenance: Offering ongoing support and maintenance services, manufacturers help businesses minimize downtime and extend the lifespan of their equipment.

Choosing the Right Manufacturer

Selecting the right industrial control panel manufacturer is crucial for businesses aiming to enhance their operational efficiency. Here are some factors to consider:

- Experience and Expertise: Look for manufacturers with a proven track record and expertise in your specific industry.

- Customization Capabilities: Ensure the manufacturer can tailor solutions to meet your unique operational requirements.

- Quality Assurance: Investigate the manufacturer’s quality control processes to ensure the reliability and durability of their products.

- Customer Support: Opt for manufacturers that offer robust after-sales support to address any issues that may arise.

In conclusion, the contribution of an industrial control panel manufacturer is indispensable to the efficiency and success of US manufacturing. By providing customized, reliable, and technologically advanced solutions, these manufacturers empower businesses to optimize their operations, reduce costs, and enhance safety. As industries continue to evolve, the demand for sophisticated control panels will only grow, reinforcing their role as a cornerstone of modern manufacturing efficiency. By carefully selecting the right manufacturer, businesses can ensure they are equipped with the tools necessary to thrive in an increasingly competitive market.