Industrial operations depend on pipes and tubing. Each operation requires exact types of piping and specific materials to work as designed and per the substance or liquid to be transferred. Pipes and tubing also come in various sizes to maximize the transfer of materials efficiently and quickly.

Quality industrial pipe supply ensures that these essential components arrive where and when needed and according to job specifications.

Types of Industrial Pipes

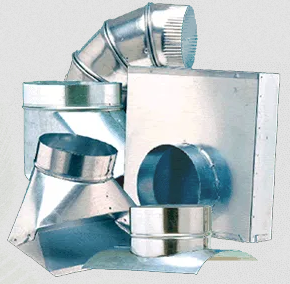

Industrial pipes are designed and implemented according to the transfer system’s purpose and the nature of the substances involved. The following is a list of some of the more common types of piping made available by industrial pipe supply services.

-

Boiler Tube

-

Cement-Lined

-

Carbon Steel Pipe

-

Chrome Pipe

-

Composite Pipe

-

Ductile Iron Pipe

-

Stainless Steel

-

Copper Tubing and Pipe

-

Tubing for Instrumentation

-

Finned Tube

-

HDPE

-

Coated and Painted Pipe

-

PVC and CPVC

-

Alloys

Pipe supply can also provide pipes and tubes in a range of sizes, wall thicknesses and pressure classes. Sizes tend to run from 1/8″ to 60″. Pipe walls can run from Schedule 10 to double extra strong, tubing thicknesses from 0.016″ to 0.75″ and pressure classes from 125# to 9000#.

Pipes and Tubes to Spec

Not only can industrial pipe supply meet material type demands, but these services can also maintain current approved manufacturer lists for separate facilities, composed according to approved component manufacturers or countries of origin.

Whatever the job or manufacturing specifications, pipe supply will understand the factors involved and expedite deliveries.